What is the Most Common Cause of Compression Fitting Leaking?

A compression joint, o ring or fitting is a plumbing device used to connect the joint of a pipe to a fixture, it comprises a compression nut, compression seat, and a compression ring made of a strong material like stainless steel to create a tighter seal between the joint of two pipes.

However, if the fitting is not well installed or begins to wear out due to improper use, one may start to experience leaking problems which may further damage the copper pipe or the entire system resulting in a shortage in the water supply.

Causes of a Compression Fitting Leaks

There are multiple different reasons why a compression fitting may experience leaks.

-

Damaged Steel Pipe

One possible cause may be a damaged steel pipe, this occurs when compression fittings do not remain stationary since they are moved forth and back. This, in turn, makes them begin to either dent or bend the compression fittings and ends up getting damaged, thus preventing the compression fittings ring from creating a tight seal around the end of the pipe, which then springs small leaks which gradually develop into larger ones.

-

Over-tightened Nut

Secondly, over-tightening the nut of compression fittings can cause the compression fitting to leak. Over-tightening the steel nut of compression fittings may cause the compression ring to deform, lose its shape and prevent it from creating a tight seal around the new nut in the steel, which in turn results in a leaky, compression fitting leaking out.

-

Under-tightened Nut

Under-tightening copper pipe may cause a leaking, this leak is simply because water can easily seep through the left gap between the steel compression inlet valve and the steel pipe. This action results in leaks in the kitchen sink pipes connection, further damaging the connection if not attended to.

-

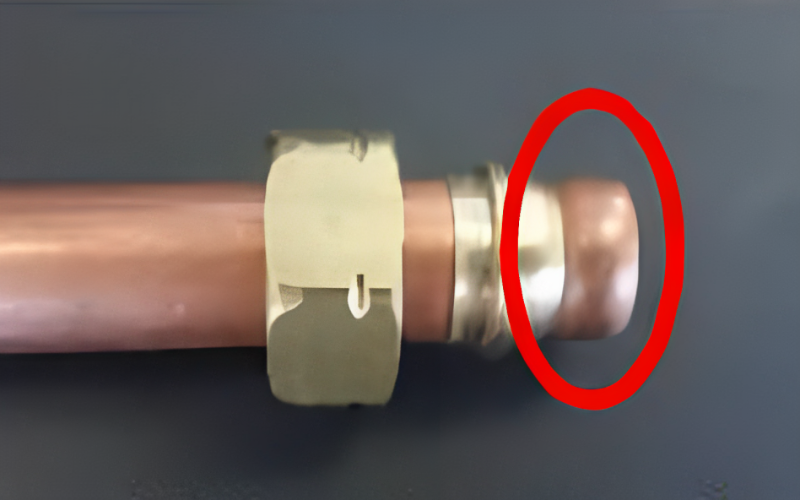

Double Compression

Double compression is another cause of leaks in compression fittings, this happens when you reuse an old compression fitting that already has a compression fitting ring on the male end of the copper pipe in it and then add a new compression fitting with another ring.

The two rings can interfere with one another, leading to the deformation of the first compression ring. They may prevent them from creating a tight seal around the copper pipe, which may automatically result in a leak.

-

Damaged Pipe

Additionally, a damaged pipe can be a cause of leaky compression. If the pipe is deformed or has a crack, this mostly happens when the pipe is bent; hence it will not be able to create a tight seal around the steel pipe which can result in a leak.

In case of a leak, how do you fix a leaking compression fitting?

When compression fittings leak, they cause inconveniences and unnecessary damage to pipes connected to the kitchen sink, sinks and other plumbing connections. Therefore they should be repaired as soon as possible to avoid unnecessary further pipe damage, which may be costly to install new plumbing or replace compression fitting.

Here are a few DIY tips on handling leaking in your home's supply pipe.

-

Inspect Supply Pipe Fittings

First, you must inspect the supply pipe fittings well and double-check them for any signs of corrosion or damage. If there are any damages, replace the fittings or consult professional plumbers to fix the leak.

When your compression fitting is leaking, first turn off the water supply by closing the inlet valve; otherwise, failing to close it may result in a wet mess.

Then loosen the compression fitting nut and then re-tighten it. Approximately 100% of professional plumbers use this simple trick since the leaking problem may be caused by under-tightening or over-tightening of the compression pipe joint compound and fitting nut.

For old nuts, this action breaks up corrosion on old nut threads hence yielding no leakage and a tighter seal.

-

Use Teflon tape

Another tip to fix compression fittings leaks is to tighten them by using Teflon tape on the threads of the compression fitting to create a better seal and stop leaking out. You can easily wrap the tape around the compression fitting and threads in a clockwise direction to cover the entire threads hence creating a tighter seal to prevent and stop the leaking.

-

Replace Compression Ring

To also fix leaks, reassemble the fittings once you have replaced the compression ring and hand tighten the brass ring to the nut, then use a wrench to tighten it a little further until you feel resistance. Using a wrench for this trick creates more pressure and a tight seal and hence will stop the fitting from leaking.

-

Clean with Emery Cloth

Clean the compression fittings thoroughly with an emery cloth to remove dirt before reassembling them. Cleaning them removes any accumulated dirt or corrosion, creating a tighter seal to fix the leakage.

Additionally, if none of the tips seems to work properly, you may need to consult a plumber or the manufacturer of the fitting for assistance. You may need to replace the entire fitting when the leaks persist.

Why use plumbers' tape and pipe joint compound?

A pipe joint compound also known as a pipe dope, is a paste-like substance used to create a better seal in between threaded pipe and stationary connections. A plumber's tape is a thin layer of tape wrapped around the threads and stationary connections of a pipe before it is screwed into place.

A plumber's tape is made of a slippery material which allows the male threads to slide and be tightened more easily. It also fills any gap between hence creating pressure and a tighter seal which prevents leaks. The male threads are wrapped with Teflon glued to tighten the tape. Moreover, the tape is affordable and easy to use, making it an excellent choice for DIY homeowners.

On the other hand, a pipe dope is applied on the threads of the fittings before it is put into place. It fills any gaps between the threads, creating a tight seal that prevents any leaks. Additionally, it is more viscous than a plumber's tape, making it a good choice for connections that are difficult to access.

Both plumber's tape and pipe joint compound are vital in preventing leaks; however, they both have different applications. The pipe joint compound is effective for larger connections or pipe connected while the plumber's tape is suitable for smaller connections or pipe connections. Whichever one's tool of choice, you should make sure you carefully follow the manufacturer's guidelines or instructions before use.

Solid copper supply lines

They are commonly used in plumbing systems to carry water from the main supply line to various fixtures in a building. In case you are having trouble handling leaky compression fittings on a solid copper pipe connected to supply lines, you may need to tighten the nut a little more. It is necessary to address leaks as soon as they are noticed to prevent other plumbing issues or further damage.

How Do I Stop My Compression Fitting from Leaking?

If the pipe has an oil leak, then loosen the nuts. Most plumbers do it from time to time. By loosening the nuts and tightening them again, it will remove corrosion from the threaded screws which prevents leakage. Because corrosion is removed, compression nuts are tightened to the same degree they are. This means that the seals have tightened considerably. Please shut the valve before starting. This will stop the water supply. You may get soaked and wet after doing so. It's easy to use wet cloths or buckets if you want to catch leaking water while you loosen the nuts.

FAQs

Below are sampled questions frequently asked about leaky compression fitting.

How do you tighten a compression nut?

To tighten a compression nut counterclockwise, you need two wrenches; one to hold the pipe and the other to slide and tighten the nut. First, you turn off the water supply to the valve you intend to work on and lay a dry towel to collect any water that may leak out when loosening copper pipe and tightening the nut.

Secondly, use an adjustable wrench to hold the nut against the steel pipe carefully not to interfere with fitting the pipe. Use the other adjustable wrench to tighten the compression nut counterclockwise until it is snug. Be cautious enough not to over-tighten the nut since it may result in a leak or even deforming the pipe around it.

Turn on the water supply to check for any leaking. If the leaking persists or you are unable to tighten the nut, you may need to replace or loosen the nut or the entire compression fitting or consult a plumber for assistance.

How do you fix a leaking compression fitting?

Before you commence fixing or replacing a leak in compression fittings, turn off the water supply by closing the inlet valve to prevent a wet mess. Using a pair of standard pliers, grasp onto a brass ferrule, carefully loosen it up and pull it off.

After the removal of the brass ferrule part, use a file for deburring the end of the pipe until it has an even smooth finish. It is advisable not to return the old compression nut since replacing it is more likely to result in a leak as it may be worn out or even corroded.

Therefore, take off the old compression nut and compression seat, replace it with a new compression nut and slide the compression ring. Afterward, hand tighten the entire fitting, then use an adjustable wrench to tighten it a little bit more, then turn on the water supply to gauge the progress.

Can you use Teflon tape on compression fittings?

This question poses a challenge to most people, but the answer is yes; however, be extra keen not to use too much tape as it can cause interference with the threads causing them to join together. This in turn makes it difficult for the fitting to create a tighter seal to tighten the screw to the nut. Therefore, use only enough tape and ensure it is evenly distributed around the threads since the tape helps to create a tighter seal and prevents leaks.

Do you use sealant on compression fittings?

Sealant is commonly used on fittings; for compression fitting leaks however, it is not necessary. They are specially designed to create a tight seal without the need for additional external sealant. In case your compression fittings are experiencing leaks, you can use a small amount of Teflon tape on the threads of the fitting to help create a better seal.

However, it may interfere with compression fitting's ability to create a tighter seal if used in excess amounts. Additionally, you may need to consult a professional plumber or the manufacturer for assistance if the leaking persists.

Conclusion

A compression fitting is likely to experience leaking problems. Any leaks noted should be addressed sooner to prevent the leaks from progressing to greater damages which may be costly to repair and install. Luckily, at Ace Compression Fittings, we have top-quality fittings for your repair needs. Contact us today at 800-888-8769.