Stainless Steel Fittings & Flanges - Pipe Fittings

Stainless steel fittings and flanges play a pivotal role in pipe systems' efficient functioning and durability. With their exceptional strength, corrosion resistance, and versatility, these components have become the preferred choice for various industries.

Whether you're a professional plumber, an industrial engineer, or a DIY enthusiast, understanding the importance of high-quality fittings and flanges is crucial for a successful plumbing system.

They ensure a leak-free and efficient flow of liquids or gases. With their exceptional durability, corrosion resistance, and versatility, stainless steel fittings and flanges have become the preferred choice in various industries, including construction, oil and gas, chemical processing, and more.

Benefits of Stainless Steel Fittings & Flanges

Stainless steel fittings and flanges offer numerous advantages that make them highly sought after in industrial applications.

Firstly, they possess remarkable corrosion resistance, making them ideal for use in environments where exposure to moisture, chemicals, or extreme temperatures is common. This resistance helps prevent leaks and ensures the longevity of the piping system.

Furthermore, stainless steel fittings and flanges provide exceptional strength and durability. They can withstand high pressure, heavy loads, and mechanical stress without compromising performance. This robustness reduces the risk of system failures and subsequent costly repairs, thus offering long-term cost savings.

What is stainless steel pipe fitting?

These fittings are used to connect and redirect pipes in different directions, sizes, and shapes. They include elbows, tees, couplings, reducers, and valves. Stainless steel pipe fittings are available in different pressure ratings and connection methods, such as threaded, socket weld, and butt weld.

Types of Stainless Steel Fittings

Stainless steel fittings and flanges come in various configurations, allowing seamless integration into various piping systems. Some common types include:

-

Bushings

Bushings are versatile stainless steel fittings used to connect pipes of different sizes. They are cylindrical in shape, with one end larger than the other, allowing for easy insertion into different pipe sizes. Bushings help reduce or increase the pipe's diameter, ensuring a secure and leak-proof connection. These fittings are often used when transitioning from a larger pipe size to a smaller one, enabling the use of various components with different diameters.

-

Adapters

Stainless steel adapters are crucial components that connect pipes or hoses of different types or sizes. They are designed with different end connections to accommodate the diverse needs of industries.

Adapters can have male or female npt, or female npt threads, allowing for flexibility in connecting pipes, valves, or equipment. They are widely used in fluid transfer systems, ensuring compatibility and seamless integration between different components.

-

Couplings

Stainless steel couplings join two pipes together, providing a strong and leak-resistant connection. These fittings come in various designs, such as socket weld, threaded, or quick-connect couplings. Socket weld couplings require the pipes to be inserted straight into the socket and then welded together for a secure joint.

Threaded couplings, on the other hand, have internal and external threads that allow for easy assembly and disassembly. Quick-connect couplings are popular for their convenience and time-saving nature, as they enable rapid connection and disconnection without the need for additional tools.

-

Elbows

Stainless steel elbows are fittings with a curved design that enables changes in the direction of a piping system. They are available in different angles, commonly 45 degrees and 90 degrees, allowing for flexibility in pipe routing.

Elbows help navigate obstacles or create smooth bends in the piping system, optimizing flow and reducing pressure drop. These fittings are essential in plumbing, HVAC (heating, ventilation, and air conditioning), and industrial applications.

-

Nipples

Stainless steel nipples are short, threaded connectors used to join two pipes or extend the length of an existing pipe. These fittings come in various diameters and lengths, making them suitable for connecting pipes of different sizes and configurations.

Stainless nipples are known for their excellent resistance to corrosion, making them ideal for use in environments with high moisture or chemical exposure. They are suitable for plumbing, petrochemical, food processing, and pharmaceutical applications.

-

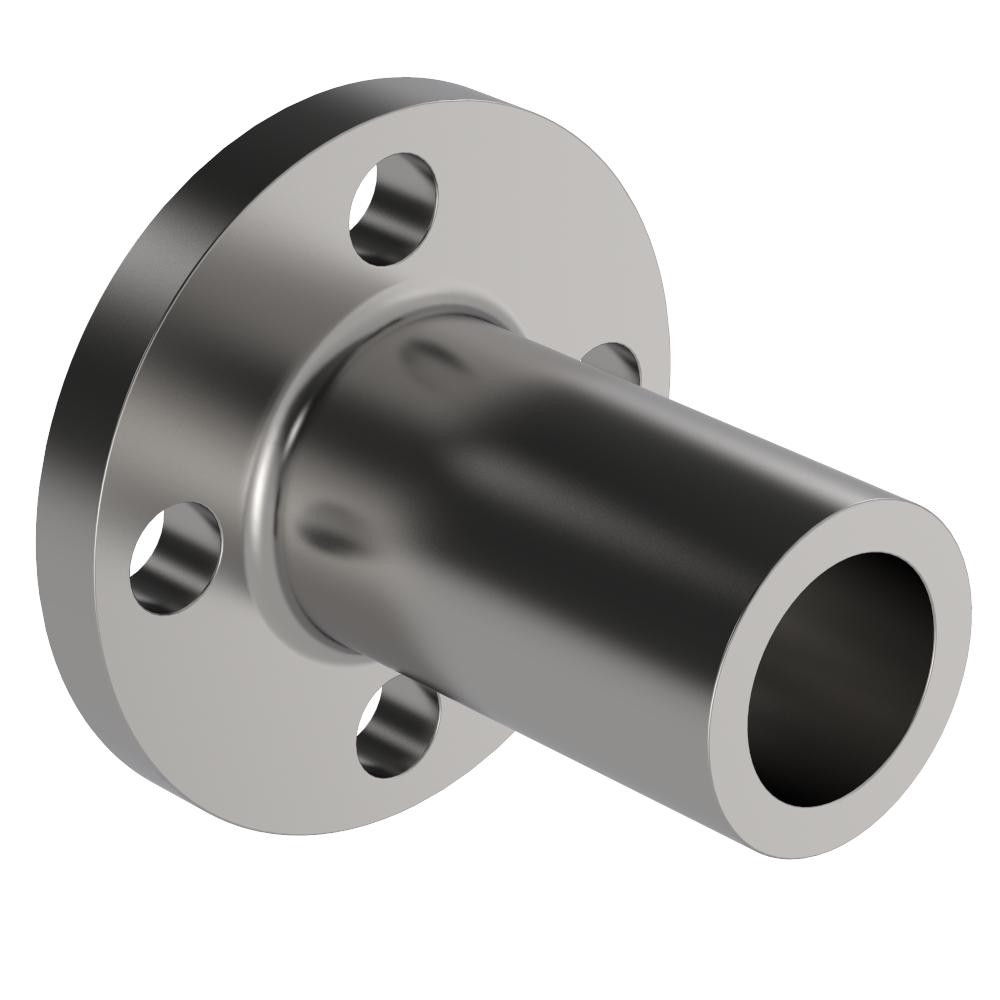

Flanges

Flanges are essential components used to connect pipes, valves, and filters to other equipment. These flat, circular discs feature a center opening and bolt holes around the circumference, allowing for easy installation and secure connections.

These stainless fittings provide superior strength, leak-free sealing, and resistance to extreme temperatures and pressures. They are commonly used in pipelines, oil and gas refineries, power plants, and offshore installations. Flanges are available in different designs, including slip-on, weld neck, socket weld, and blind flanges, each serving specific installation requirements.

-

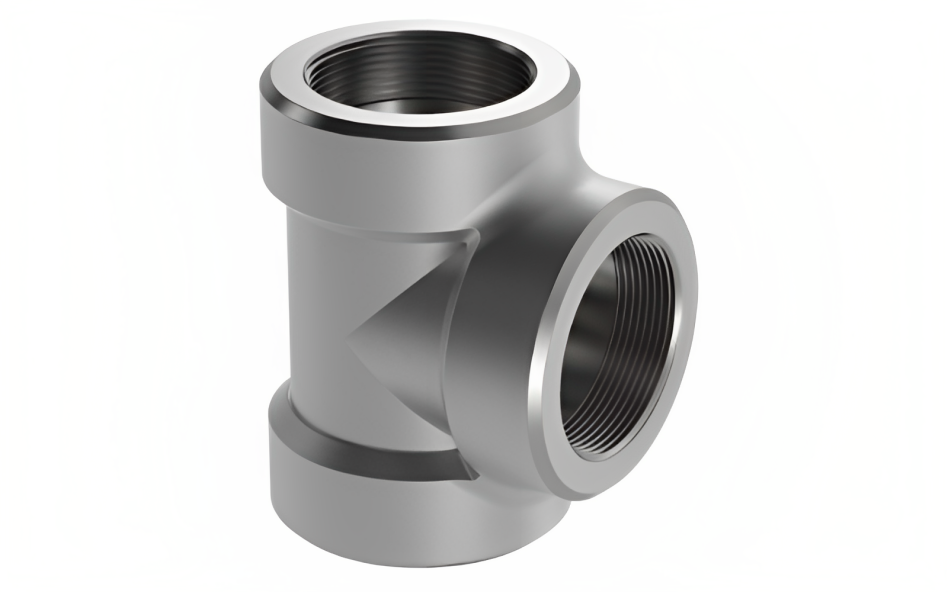

Tees

Tees are fittings with a T-shaped design used to create a branch connection between three pipes. Stainless steel tees allow the flow of fluids to be divided or combined, making them crucial for creating complex piping systems.

These fittings are available in various configurations, such as equal tees, reducing tees, and barred tees, providing flexibility in accommodating different pipe sizes and flow requirements. They are widely used in oil and gas, chemical processing, water treatment, and HVAC systems.

-

O-Lets

O-Lets, or branch connections or pipe outlets, are specialized fittings that create branch connections in piping systems. These fittings are welded onto existing pipelines, allowing additional pipelines or equipment to be attached.

They are known for their structural integrity, high pressure and temperature resistance, and excellent corrosion resistance. They are commonly employed in oil and gas, petrochemical, power generation, and pharmaceuticals, enabling efficient and reliable branching in complex piping networks.

What is stainless steel flange?

Flanges connect pipes, valves, and other equipment in a piping system. They provide a secure and leak-proof joint, allowing easy disassembly and maintenance. Stainless steel flanges come in different designs, catering to diverse application requirements.

Types of flanges

Flanges are vital components in piping systems to create secure and leak-proof connections between pipes, valves, and equipment. They come in various types, each designed for specific applications and installation methods.

-

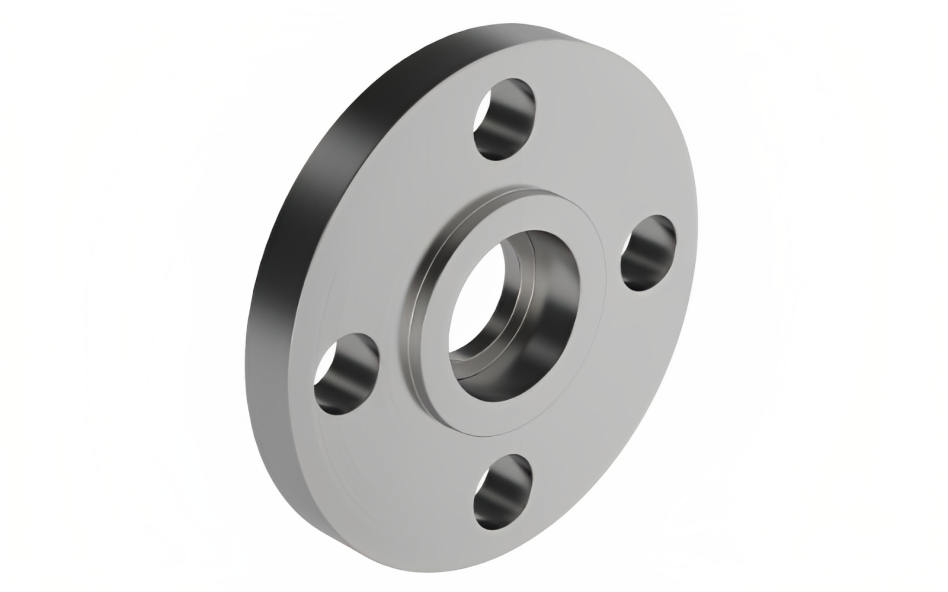

Slip-on flange

The slip-on flange is one of the most widely used flange types due to its simplicity and ease of installation. This flange has a circular shape with a flat, slightly larger diameter than the pipe it connects to. It is slipped over the pipe and then welded on the inside and outside to provide a secure and reliable connection.

Slip-on flanges are commonly used for low-pressure applications and in systems where frequent disassembly is not required.

-

Threaded flanges

Threaded flanges feature an internal thread that matches the external thread on the pipe or fitting, allowing them to be easily screwed together. This type of flange is commonly used in small-diameter piping systems or where frequent disassembly is necessary.

Threaded flanges provide a strong connection and are suitable for low-pressure applications. They are often found in plumbing, fire protection, and other industrial applications.

-

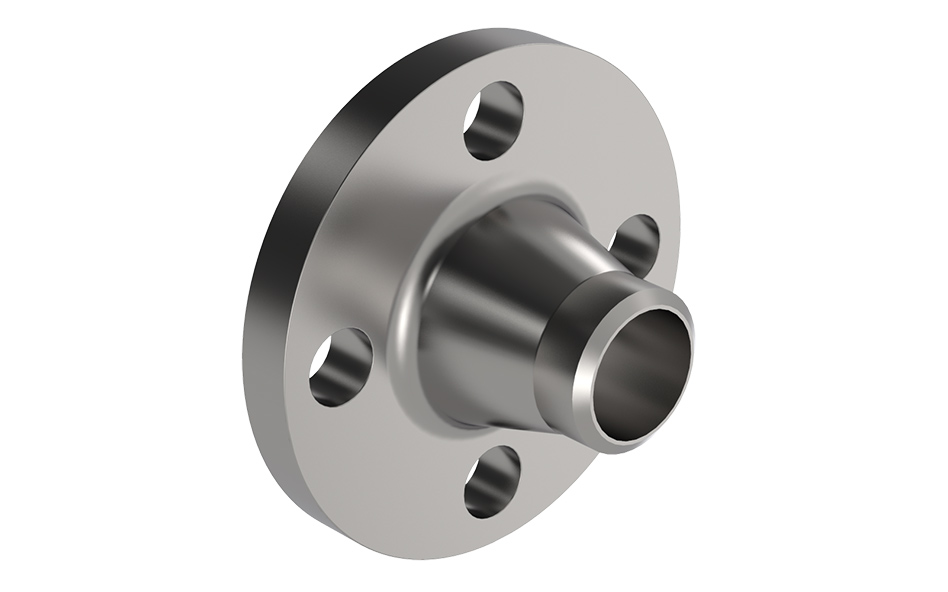

Weld Neck Flanges

Weld neck flanges are known for their excellent structural integrity and high-pressure resistance. These flanges have a long, tapered hub with a circular weld bevel at the end. The neck of the flange is welded to the pipe, ensuring a robust connection.

Weld neck flanges are primarily used in high-pressure and high-temperature applications, such as oil refineries, chemical plants, and power generation facilities. Their design helps reduce stress concentration and promotes smooth, fluid flow.

-

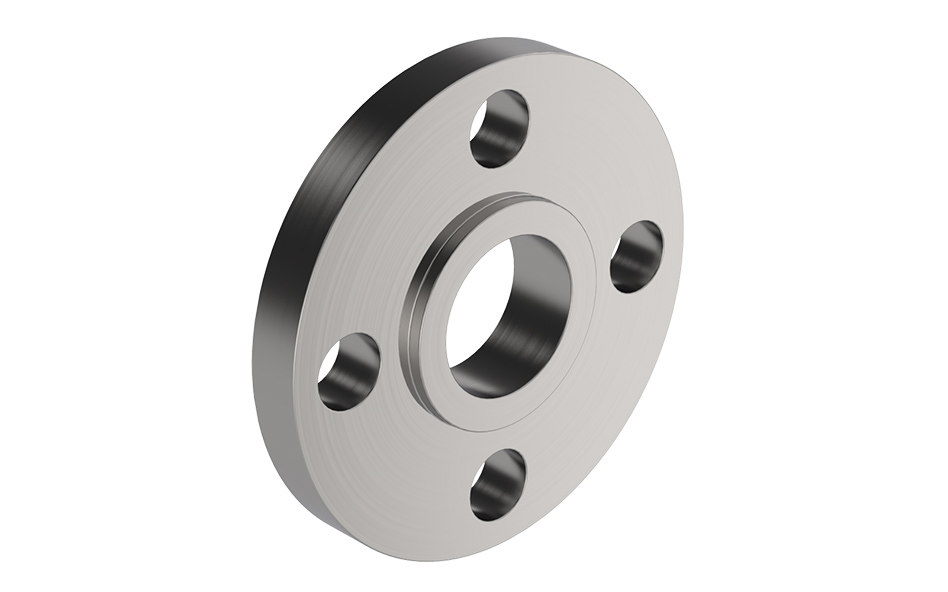

Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges but have a socket-like end that fits over the pipe. The pipe is inserted into the socket and then fillet welded on the outside to create a secure connection.

Socket weld flanges are commonly used in small-bore piping systems where there is a need for high-pressure and tight sealing. They are widely used in petrochemical, oil and gas, and refineries.

-

Blind Flanges

Blind flanges, as the name suggests, are used to seal the end of a pipe or vessel. They are solid disks with no openings, providing a reliable closure to prevent leakage. Blind flanges are commonly used in systems where regular inspection or pipe cleaning is unnecessary.

These flanges also find application in situations where future expansion or connection of additional equipment may be required. Blind flanges can be easily installed and removed, making them a practical choice for many industrial applications.

-

Lap Joint Flanges

Lap joint flanges have two main components: a flat, circular plate and a separate ring that holds the plate in place. The plate is typically made of a material similar to the pipe being connected, while the ring, known as a stub end, is made of a different material, often a lower-cost alloy.

Lap joint flanges are popular when the easy alignment of the bolt holes is required or when disassembly and frequent maintenance are necessary. These flanges allow rotation of the stub end, which provides flexibility during installation, alignment, and repairs.

-

Long Neck Weld Flanges

Long-neck weld flanges, also known as weld-neck flanges, are designed for high-pressure applications. They feature a tapered neck that gradually merges into the pipe, providing reinforcement and reducing stress concentration.

The elongated neck ensures smooth flow transition, minimizing turbulence and pressure drop. Long neck weld flanges offer excellent strength and are widely used in critical systems such as oil and gas pipelines, power plants, and chemical processing industries.

Applications of Stainless Steel Fittings & Flanges

Stainless steel fittings and flanges find extensive usage across multiple industries due to their adaptability and reliability. Here are some key application areas:

-

Oil and Gas Industry

The demanding conditions of the oil and gas industry necessitate materials that can withstand high pressure, extreme temperatures, and corrosive environments.

Stainless steel fittings and flanges excel in these areas, making them indispensable in pipelines, refineries, offshore platforms, and petrochemical plants. Their resistance to rust and chemical reactions ensures the integrity of the systems, while their dimensional accuracy and ease of installation contribute to the efficiency of operations.

-

Construction Industry

The construction industry heavily relies on stainless steel fittings and flanges due to their exceptional strength, reliability, and resistance to corrosion. These components provide crucial support and connectivity in structural applications, such as bridges, high-rise buildings, and stadiums.

Stainless steel fittings and flanges are also extensively used in plumbing systems, HVAC (heating, ventilation, and air conditioning) installations, and sanitary applications. Their leak-resistant properties and longevity make them a preferred choice for residential and commercial projects.

-

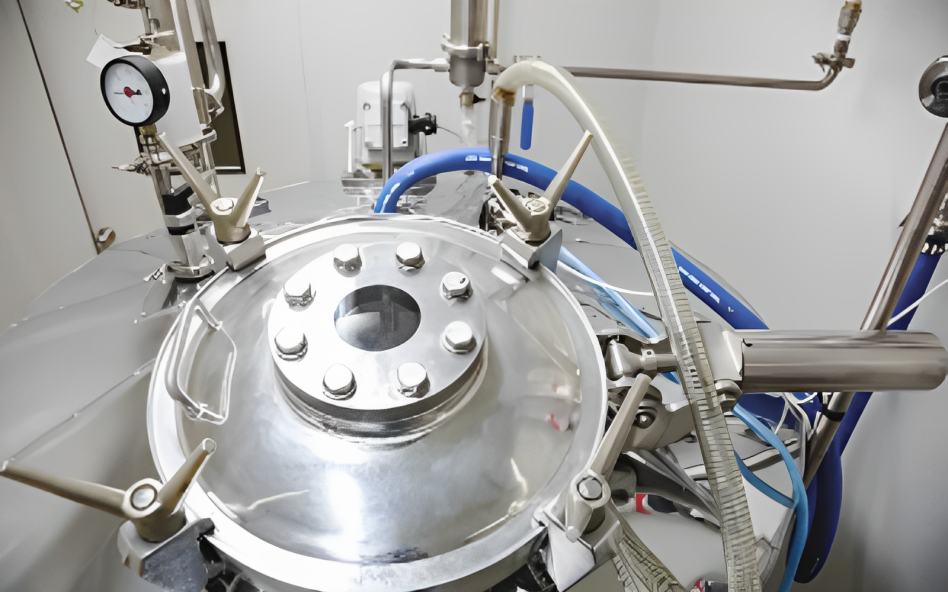

Chemical Processing

Chemical and petrochemical industries handle aggressive chemicals and operate under high-pressure conditions. Stainless steel fittings and flanges offer excellent resistance to a wide range of corrosive substances, making them an ideal choice for these applications.

They are extensively used in reactors, storage tanks, piping systems, and other equipment, ensuring the safe and efficient handling of chemicals and petrochemicals.

-

Food Processing and Pharmaceuticals

Stainless steel fittings and flanges ensure hygienic and contaminant-free processes in the food processing and pharmaceutical industries.

These components are widely used in equipment such as tanks, pumps, valves, and piping systems, where maintaining product purity is critical.

Stainless steel's non-reactive nature, easy cleanability, and resistance to bacterial growth make it an ideal choice for maintaining stringent hygiene standards in food and pharmaceutical production facilities.

-

Water Treatment

Water treatment plants and desalination facilities rely on stainless steel fittings and flanges for their durability and resistance to corrosion in the presence of chemicals and saltwater.

These components are used in various stages of the water treatment process, including pumping stations, filtration systems, and distribution networks. Stainless steel's ability to maintain water quality and resist scaling and pitting ensures the reliability and longevity of these critical infrastructure systems.

Why Our Threaded Stainless Steel Pipe Fittings?

Introducing our high-quality threaded stainless steel pipe fittings in stock, designed to provide exceptional performance and durability for various plumbing and industrial applications. Crafted with precision and expertise, these fittings are the perfect choice for ensuring a secure and leak-free connection in your piping systems.

Made from premium stainless steel, our threaded pipe fittings offer exceptional corrosion, rust, and wear resistance, making them ideal for indoor and outdoor use. Whether you're working with water, gas, chemicals, or other fluids, our fittings are engineered to withstand the harshest conditions, ensuring long-lasting performance and peace of mind.

Their reliable and secure connection with PTFE tape sets our threaded stainless steel pipe fittings apart. With precision-cut threads, these fittings provide a tight seal, minimizing the risk of leaks and ensuring efficient fluid flow. Their threaded design allows easy installation and disassembly, providing convenience during maintenance and repairs.

At our company, quality is our top priority. We meticulously adhere to strict manufacturing standards, ensuring that each threaded stainless steel pipe fitting meets or exceeds industry norms. Our fittings undergo rigorous pressure rating testing and inspection, guaranteeing consistent quality and reliability in our products.

FAQS

-

Is stainless steel good for plumbing?

Stainless steel is an exceptional choice for plumbing due to its durability, corrosion resistance, hygienic properties, and versatility. By opting for stainless steel pipes and fittings, you invest in a long-lasting and reliable plumbing system that will continue to perform optimally for years.

Say goodbye to worries about leaks, rust, or compromised water quality, and enjoy peace of mind with stainless steel plumbing.

-

What is the disadvantage of stainless steel in plumbing?

Stainless steel is undoubtedly popular for plumbing systems due to its durability and corrosion resistance. However, it is crucial to be aware of the disadvantages of this material.

Higher costs, potential corrosion under specific conditions, installation challenges, and lower thermal conductivity are among the drawbacks that need to be considered. By weighing these factors against the specific requirements of your plumbing project, you can make an informed decision regarding the suitability and price of stainless steel or explore alternative materials that may better align with your needs and budget.

-

Can a copper pipe be replaced with stainless steel?

Copper pipes have been a reliable choice for plumbing systems; stainless steel pipes offer numerous advantages, making them a compelling alternative.

Their durability, corrosion resistance, and ability to withstand high temperatures make them an excellent choice for demanding applications. However, weighing the higher cost and considering professional installation when opting for stainless steel pipes is crucial.

If you want to replace your copper pipes with stainless steel, consult a reputable plumber who can guide you through the process and ensure a seamless transition. Invest in your plumbing system's long-term health and efficiency by considering stainless steel pipes as a viable and durable option.

-

Can you use stainless steel fittings on copper tubing?

using stainless steel fittings on copper tubing is a viable option, offering durability, corrosion resistance, and strength. You can ensure a secure and leak-free connection by employing compatible joining methods such as compression fittings or soldering.

Remember to consider the specific environment and conditions in which the fittings and tubing will be used and choose the appropriate grade of stainless steel for optimal performance.

For further assistance or any specific queries, don't hesitate to contact a trusted professional in the field. Ace Compression Fittings is one of the best vendors. Get in touch with the sales team.

-

What does SS stand for in piping?

In the realm of piping, "SS" is an abbreviation for "Stainless Steel." Stainless steel is a steel alloy with a minimum of 10.5% chromium. This high chromium content forms a protective layer on the surface of the steel, known as the passive film, which makes it highly resistant to corrosion and oxidation.

Combining other elements like nickel, molybdenum, and titanium, stainless steel gains enhanced strength, durability, and resistance to extreme temperatures.

-

What are stainless steel 304 pipe fittings?

Are you searching for high-quality pipe fittings that offer both reliability and exceptional performance? Look no further than stainless steel 304 pipe fittings. Engineered to meet the diverse needs of various industries, these fittings have become a go-to choice for professionals seeking dependable solutions for their piping systems.

Stainless steel 304 pipe fittings are crafted from a specific grade of stainless steel known as 304, renowned for its excellent corrosion resistance and robustness. This alloy contains a composition of chromium, nickel, and small amounts of other elements, rendering it highly resistant to oxidation, heat, and chemicals.

As a result, these fittings can withstand extreme conditions and maintain their structural integrity over an extended period.

-

When installing stainless steel tubing, what type of fittings should be used?

Stainless steel tubing is widely preferred in various applications due to its excellent corrosion resistance, strength, and aesthetic appeal. To complement these qualities, it's essential to select fittings that are specifically designed for stainless steel tubing.

One commonly used fitting type for stainless steel tubing is compression fittings. These fittings consist of a nut, a ferrule, and a body, which are tightened to create a secure and leak-free connection. Compression fittings are known for their simplicity and ease of installation, making them a popular choice among both professionals and DIY enthusiasts.

Another option is push-to-connect fittings, also known as quick-connect or push-in fittings. These fittings have gained popularity recently due to their convenient installation process. With push-to-connect fittings, you insert the female threads tubing into the fitting, and the internal components create a tight seal automatically.

This makes them an excellent choice for projects that require lead-free frequent disassembly and reassembly.

-

What are the three types of pipe fittings?

There are three main categories of pipe fittings: compression, soldered, and threaded.

Compression Fittings: Compression fittings are widely used for joining pipes in residential and commercial applications. These fittings are designed to create a tight seal by compressing a ring or ferrule onto the pipe. The compression fitting consists of three main components: the compression nut, the compression ring, and the body.

Soldered Fittings: Soldered fittings, also known as sweat fittings, are commonly used in plumbing systems. They are ideal for joining copper pipes together. The soldering process involves heating the fitting and pipe to melt a filler metal (solder) that creates a strong bond when cooled. This method ensures a secure and leak-free connection.

Threaded Fittings: Threaded fittings utilize threads to connect pipes and create a sealed joint. These fittings have tapered or parallel threads on both the interior and exterior surfaces, allowing them to be screwed together. Threaded fittings are typically made from brass, stainless steel, or PVC.

They offer excellent versatility and are commonly used in applications requiring disassembly and reassembly, such as repairs or installations needing adjustments over time. However, it is crucial to use proper sealing techniques, such as thread seal tape or pipe dope, in order to ensure a watertight connection.

-

Do you need special dies to thread stainless steel pipe?

When it comes to threading stainless steel pipe, it's highly recommended to use special dies specifically designed for this purpose. These specialized dies are crafted with the strength and hardness to effectively cut threads into the tough stainless steel surface. Regular dies may not be able to withstand the demanding nature of stainless steel, leading to ineffective results and potential damage to the material.

Stainless steel has a higher strength and hardness than other commonly threaded materials, such as brass or copper. This means that ordinary dies, which are designed for softer metals, may not be able to penetrate the stainless steel properly, resulting in inaccurate or weak threads. Using special dies ensures clean and precise threading, providing you with reliable connections that can withstand the test of time.

-

Why is stainless steel not used in plumbing?

Have you ever wondered why stainless steel, renowned for its durability and sleek appearance, isn't commonly used in plumbing systems? While stainless steel finds its place in various industries, such as architecture and cookware, it isn't the top choice for plumbing applications.

Stainless steel is indeed highly resistant to corrosion, a trait that makes it ideal for many applications. However, when it comes to plumbing, other materials, such as copper and plastic, have gained prominence due to their superior corrosion resistance. Stainless steel, while rust-resistant, can still be susceptible to localized corrosion in certain environments.

Another factor contributing to the limited use of stainless steel in plumbing is its relatively higher cost. Stainless steel pipes, fittings, and installation procedures are more expensive than alternative materials. This sort of cost differential can significantly impact construction budgets, making it less appealing for many plumbing projects, especially in residential settings.

One often overlooked aspect of plumbing is material compatibility. Stainless steel pipes may not be compatible with certain components commonly found in plumbing systems, such as brass fittings or galvanized steel pipes. These dissimilar metals can create a corrosive environment due to galvanic reactions, compromising the system's integrity over time.

Compared to other materials used in plumbing, stainless steel can be relatively inflexible and challenging to work with. Its rigidity makes it less forgiving when maneuvering around tight spaces or accommodating complex layouts. Conversely, materials like copper and plastic offer greater flexibility, enabling easier installation, especially in retrofitting or renovation projects.

-

Can you use brass fittings with stainless steel pipe?

Brass fittings and stainless steel pipes can be used together in most cases. The key lies in understanding the electrochemical properties of these materials and taking necessary precautions to prevent galvanic corrosion. Galvanic corrosion occurs when two dissimilar metals are in contact with an electrolyte, leading to accelerated corrosion.

To mitigate the risk of galvanic corrosion, it is recommended to utilize a dielectric union or a merit brass-to-stainless steel transition fitting. These fittings act as a barrier between the brass and stainless steel, preventing direct contact and minimizing the potential for galvanic corrosion. By incorporating these fittings, you can enjoy the benefits of both materials without compromising the integrity of your plumbing system.

-

Can you use push-fit fittings on stainless steel pipe?

Stainless steel pipes are known for their durability, corrosion resistance, and high strength. They are commonly used in various applications, including plumbing, heating, and industrial systems. When connecting stainless steel pipes, push-fit fittings can be an excellent choice.

One of the key advantages of push-fit fittings is their compatibility with different pipe materials, including stainless steel. These fittings typically feature a rubber O-ring or a similar sealing mechanism that creates a watertight connection when the pipe is inserted. This design allows for a secure and reliable joint, even with stainless steel pipes.

-

What type of stainless steel is used in stainless steel fittings?

Austenitic stainless steel is a commonly used stainless steel type in stainless steel fittings. This type, often called the "300 series," is known for its excellent corrosion resistance, making it ideal for applications where the fittings will be exposed to harsh environments or corrosive substances.

Austenitic stainless steel contains high levels of chromium and nickel, which provide exceptional resistance to corrosion and oxidation.

The austenitic stainless steel family has different grades, such as 304 and 316.

Conclusion

When you choose our stainless steel pipe fittings, you're investing in top-notch craftsmanship, exceptional performance, and unmatched longevity. Whether you're a plumbing professional or a DIY enthusiast, you can trust our fittings to deliver outstanding results in any application.

Experience the difference between our pipe fittings today and enjoy the peace of mind that comes with using premium-quality products. With their reliable connections, durability, and versatility, our fittings are the perfect choice for your plumbing and industrial needs. Give us a call at 800-888-8769