Bleeder Valve: Working Principle & Function

A side bleeder valve or superlok bleed valve is a type of valve used to vent pressure or release media, fluid, or air gradually from a system operator check valve that is upon pressurized liquids or air hence minimizing the risk of damaging the system. They are found on top of valves in a radiator pipe or on the sides of valves where air can be easily accessed for repair work.

They are typically made of strong materials like stainless steel, enabling them to withstand extreme pressure and harsh conditions experienced in drilling sites.

They are commonly used in automotive and industrial applications where hydraulic systems and gas turbines are used to power equipment and machinery.

Functions of a double block bleed valve

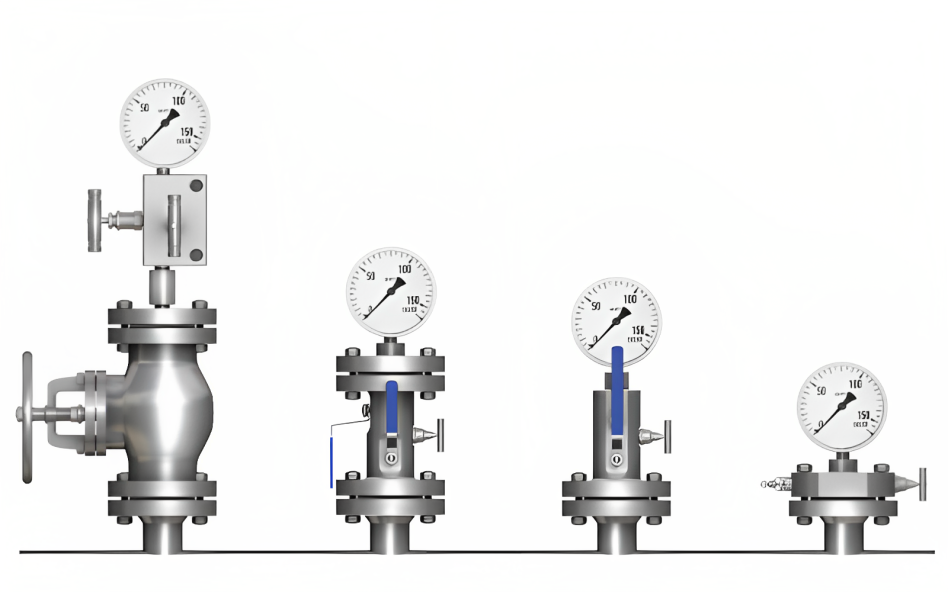

A double bleed block consists of two block valves, each separately having its mechanism used to isolate individual seals from the flow of the pressure source and one instrumentation bleed valve. They are designed to mutually work together such that when one of the instrumentation valves breaks down, the other two block valves will remain closed to each individual seal and prevent pressure from escaping.

They are purposefully designed to have zero leakage to provide extra safety in pressure systems. They are commonly used to increase the upstream pressure in many industrial applications and some fueling systems since they tolerate higher temperatures with zero leakage making them reliable in various industrial systems.

Characteristics of a double block bleed valves

Here are the features of bleed valves:

-

Durable

A double block bleed valve is designed to be durable and long-lasting even in adverse harsh conditions since they are made of high-strength materials like stainless steel, making them withstand extreme pressures and temperatures found in many industrial applications by system operators.

-

Zero Lubrication

They require only one system of zero lubrication since they are designed to be self-lubricating to operate smoothly and hence do not require additional lubrication. Its self-lubricating ability ensures the valves operate reliably and smoothly even in harsh adverse conditions.

-

Special sealant material

They do not experience any friction during the opening and closing process of threaded bleed screws since they are designed with a special sealant material that is fully filled with lubricant, which aids in reducing possible wear and tear between seating surfaces of the body cavity and seating surfaces of the check valve, block, and components of bleed valves.

They do not require external sealing or springs since their seals are mechanically energized, making them ideal for isolating the system upstream pressure from fluid flow and built-up pressure, as well as positive isolation from the pressure source fluid flow by themselves.

Applications of double block bleed valves

Double-bottom block valves are widely used in many industrial processes and applications due to their unique features, such as high resistance to corrosion, operation at high temperatures, and durability, which minimizes maintenance and repair costs.

-

Oil and Gas Industry

They are commonly used in the production of oil and gas turbines since they play a vital role in isolating high-pressure systems, preventing leakage, and facilitating maintenance or repair work.

-

Plumbing system

Additionally, they are commonly used in plant operations to isolate sections of the piping system and safely repair or replace the downstream equipment without shutting down the entire system.

-

Sampling Connections

The bleeder valves are also used in the working pressure of sampling connections, where the bleeder valve is typically installed in an upstream working pressure of sampling connection, allowing positive isolation of the sampling point from the high-pressure system. The positive isolation ensures that the working line pressure sampling process can be performed safely and efficiently without any further contamination.

In addition to sampling connections, they are also used in piping systems to provide an extra layer of isolation and safety. For instance, if a chemical spill occurs in the downstream pipeline, the bleed valve is used to carefully isolate the contaminated fluid on the shutdown side of needle valve from the section inlet, preventing the contamination from spreading further to other parts downstream of the pipe system.

How to Select a Bleeder Valve?

If you want to buy a bleed valve, there are a few things to consider. However, you can contact a reliable superlok bleed valve vendor for your needs, like Ace Compression Fittings. Here are things to look at:

-

Specific Application

When selecting a bleeder valve, it is important to note the specific application and requirements of the valves that feature the system. Type is a key factor to consider; bleed valves are available in different types. For example, there are two ball valves, gate ball valves, needle valves, and a double block. The type of valve you select depends on the specific application and requirement of the system.

-

Size

Size also matters when selecting instrumentation bleed valves; the appropriate size of the bleed valve and control valve must meet the specific requirement needed. Small-sized valves are required in some applications, while large sizes two ball valves are required in others.

-

Seal Integrity

Another key factor to consider is the seal integrity of the bleed valve. The bleed valve must be in a position to maintain a tight seal to prevent leaks and ensure the safety of the operation system. The type of seal used will highly depend on the specific requirements and application of the system.

-

Type of Assembly

During the selection process of the bleed valves, it is important to consider the type of bleed assembly isolation required. They should be able to provide the type of bleed assembly isolation required for a specific application. You can choose bleed valves on its threaded block and bleed valve with screw because of the thermal relief vent.

-

Material

Additionally, the pressure seals on the valve should be made from a material compatible with the flow of the fluid being transported to the valves to avoid the risk of contamination in the system. If you are looking for reliable material, choose the stainless steel option from Ace Compression Fittings.

FAQs

Below are sampled questions frequently asked:

Should a bleeder valve be in an open or closed position?

A tight shut off, block and bleed valve or bleeder and bleed valve should never stay open but remain closed when not in use. It is used to drain liquids or release pressure from a system and should be opened when this function is needed. Leaving a tight shut-off valve open when not in use can result in leaks and damage to the entire system, which can be pretty costly to repair.

How does an air bleed valve work?

An air bleed valve removes air from the piping systems; air gradually enters the system during installation, maintenance, or repair work. However, the air can interfere with the valves that control the system by either reducing the fluid flow or increasing the pressure, which damages the components downstream of the system. Therefore, an air bleeder valve removes air bubbles from the system and maintains proper flow and pressure of the trapped fluid.

It works by permitting air to escape under pressures from system operators, preventing fluid loss. It is installed at high points of a seating surface where much air tends to accumulate. When air enters the valve, it rises to the top and is released via a small opening.

What does the brake bleed valve do?

Brake bleed or bleeding is the process of expelling air from the hydraulic systems or brake system of a vehicle. The entire process is successfully performed by the brake line bleeder, which opens the valve on the brake lines and allows the fluid to bleed out preventing external air from entering the port.

The process is vital since it helps to ensure the safety and reliability of the brake system in a vehicle. It is one system should be regularly performed as part of the vehicle's regular maintenance routine.

Conclusion

Generally, vent tube bleed valves are essential and serve a wide range of purposes in most applications. It is typically designed to gradually expel air bubbles, harmful gas, and fluids from the system via a small port or vent tube. The needle valve is a type of check valve used to carefully control the flow of fluid in a piping system.

They are needle-like in shape, and they regulate the amount of flow of fluid. Double-block bleed valves are used to vent and drain liquids from the space between two block bleed valves. They have two outlet ports and are installed between the valves feature the isolated two bleed valves.

Steel valves are an excellent choice of use in most applications due to their ability to resist corrosion and withstand high-pressure systems and temperatures. It is also a vital component of hydraulic systems, ensuring repair work and maintenance are performed safely and efficiently.